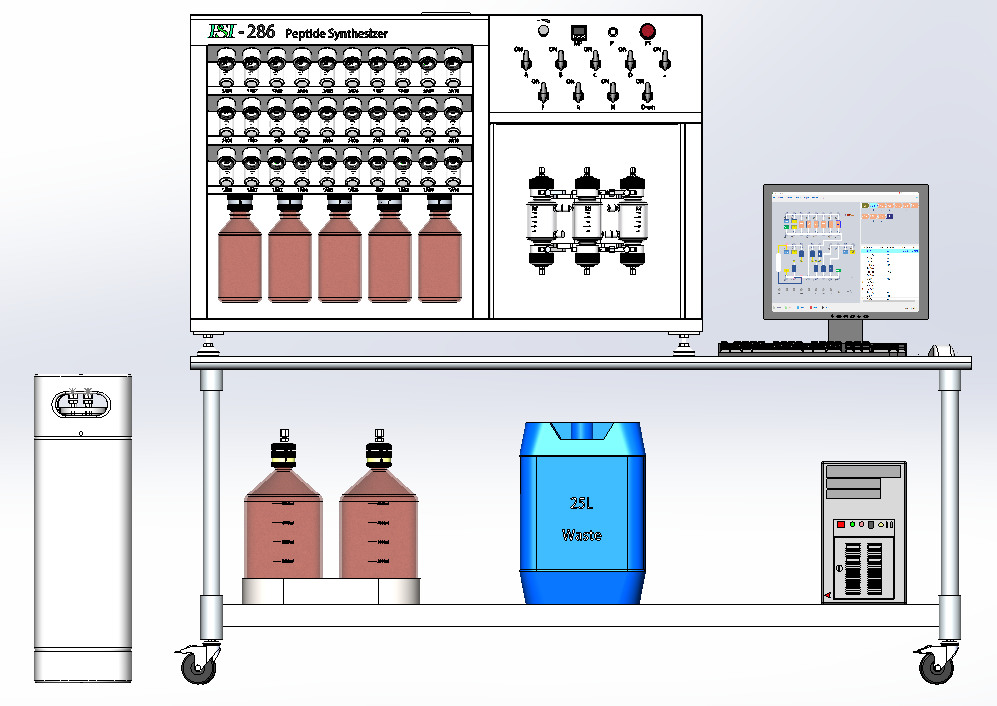

Three-channel peptide synthesizer working principle and operation process details

Release Time:2024-04-29

Number of views:1390

The Three-Channel Peptide Synthesizer is a laboratory device for the synthesis of peptides and proteins. It constructs peptide chains by the solid phase peptide synthesis (SPPS) method, which involves adding amino acids one by one to the peptide chain being synthesized. The three-channel design means that the instrument can carry out three independent synthesis reactions simultaneously, significantly improving synthesis efficiency.

I. Principle of operation:

The core part of the three-channel peptide synthesizer is three independent synthesis channels, each equipped with a mixer, reactor and wash column. These three steps are the key steps of the SPPS, and they allow the reaction conditions to be controlled and optimized at different stages.

1. Mixer: In the mixer of each channel, the amino acids to be reacted are mixed with the coupling agent to form reactive esters or analogs ready to react with the resin matrix.

2. Reactor: In the reactor, the mixture of active esters is combined with the resin matrix to form a new polypeptide chain. By controlling the reaction time, temperature and pH, the coupling reaction can be optimized to reduce errors and by-products.

3. Wash column: After each addition of amino acids, a wash column is used to remove unreacted material and by-products to ensure a pure synthesized polypeptide chain.

II. Operating Procedure:

1. Initialization: Before starting, all the reagents and materials need to be prepared, including amino acids, coupling agent, resin matrix, detergent and so on. At the same time, the synthesizer needs to be calibrated to ensure that the flow rate, pressure and other parameters of each channel are normal.

2. Starting Resin Preparation: Load the starting resin in each channel, usually the resin that has been activated, for the coupling of the first amino acid.

3. Amino acid coupling: the first amino acid is mixed with the coupling agent and then injected into the mixer to form the active ester. Next, the activated ester is transferred to the reactor and combined with the resin to form a peptide bond.

4. Washing and Deactivation: The resin is washed using a washing column to remove unreacted amino acids and coupling agent. Then, a de-activation step is performed to remove any remaining reactive ester groups.

5. Successive addition of amino acids: Repeat the above steps, adding subsequent amino acids one by one until the desired polypeptide sequence is completed.

6. Cleavage and purification of the polypeptide chain: After all amino acid coupling is complete, the polypeptide chain needs to be separated from the resin matrix and purified. This usually involves a series of pickling, washing and repurification steps.

7. Terminal processing: Terminal modifications are performed on the obtained peptide, such as the removal of end-group protecting groups, and other necessary chemical stabilization.

The three-channel peptide synthesizer realizes efficient synthesis of peptides and proteins by solid-phase synthesis. Its working principle is based on a finely regulated chemical reaction process, while the operating procedure involves a series of complex steps that require tight control of the reaction conditions.