Working Principle and Technical Analysis of Pilot Peptide Synthesizers

Release Time:2025-02-26

Number of views:1636

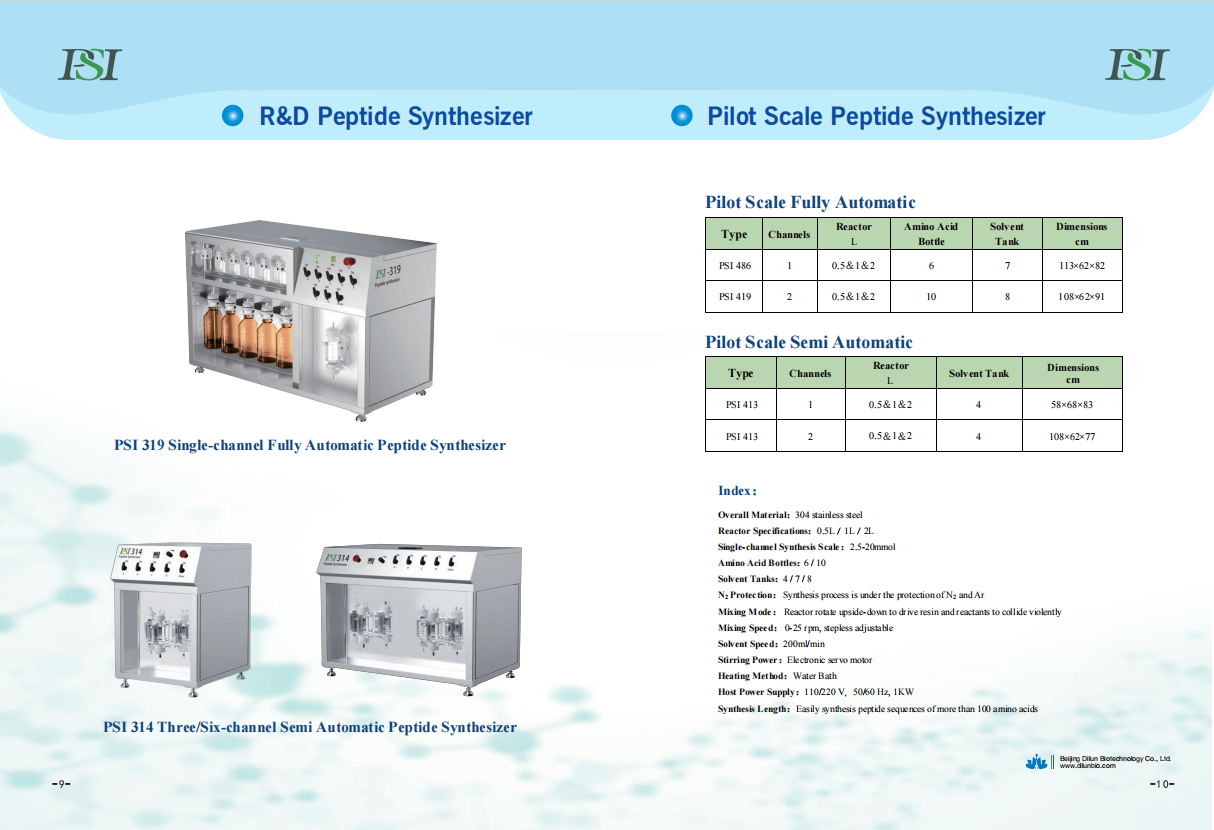

The Pilot Peptide Synthesizer plays a crucial role in the field of peptide synthesis. It can precisely and efficiently synthesise various peptide molecules with specific sequences and functions, providing a powerful tool for drug discovery, biochemical research and other fields.

I. Working Principle

The Pilot Peptide Synthesizer is mainly based on the principle of solid phase synthesis technology. It takes a solid support insoluble in organic solvents as the carrier, and usually chooses materials such as polystyrene resin. In the synthesis process, the first amino acid is first attached to the solid support through a specific chemical bond, and this chemical reaction is usually carried out in an organic solvent. Subsequently, the other amino acids are sequentially attached to the ends of the amino acids already attached to the support one by one in a designed sequence, and after each attachment, they undergo a specific chemical treatment to remove the protecting groups so that the amino acids can undergo the next step of the reaction.

The essence of this process is a condensation reaction between amino acids to build a polypeptide chain by forming peptide bonds. During the synthesis process, the reaction conditions, such as reaction temperature, reaction time, and reagent concentration, are precisely controlled to ensure the selectivity and yield of the reaction. At the same time, through the computer control system, it is possible to achieve automatic operation and precise regulation of the whole synthesis process.

Second, technical analysis

1、Design software and application: It is usually equipped with design software, through which researchers can design and optimize the peptide sequence according to their needs. The software can quickly calculate the optimal synthesis scheme, consider the compatibility of amino acids, the selectivity of condensation reaction and other potential factors to improve the synthesis efficiency and success rate.

2、Purification technology: After the completion of peptide synthesis, it usually contains some impurities, such as unreacted amino acids, residues of deprotecting reagents and so on. Equipped with a purification system, HPLC can separate the target peptide from the mixture according to the difference in the distribution of peptide molecules and impurity molecules in the solvent system, and obtain high-purity peptide products.

3、Quality control: In the process of peptide synthesis, quality control is the key to ensure the quality and performance of the synthesised peptide. Process monitoring is achieved through a variety of technical means. For example, an online monitoring system is used to monitor the parameters in the reaction process in real time, such as reaction temperature and pH value, to ensure the stability of the synthesis environment. Meanwhile, after the completion of the synthesis, advanced mass spectrometry analysis technology is used to identify the structure and purity of the synthetic peptide to verify whether it meets the design requirements.

4, automation and high efficiency: the degree of automation of the pilot peptide synthesizer is getting higher and higher. The operator only needs to input the peptide sequence and relevant synthetic parameters in the instrument operation interface, and the instrument can automatically complete a series of complex operation steps such as amino acid activation, condensation reaction, protection group removal, etc., which greatly reduces human error and improves the synthetic efficiency.