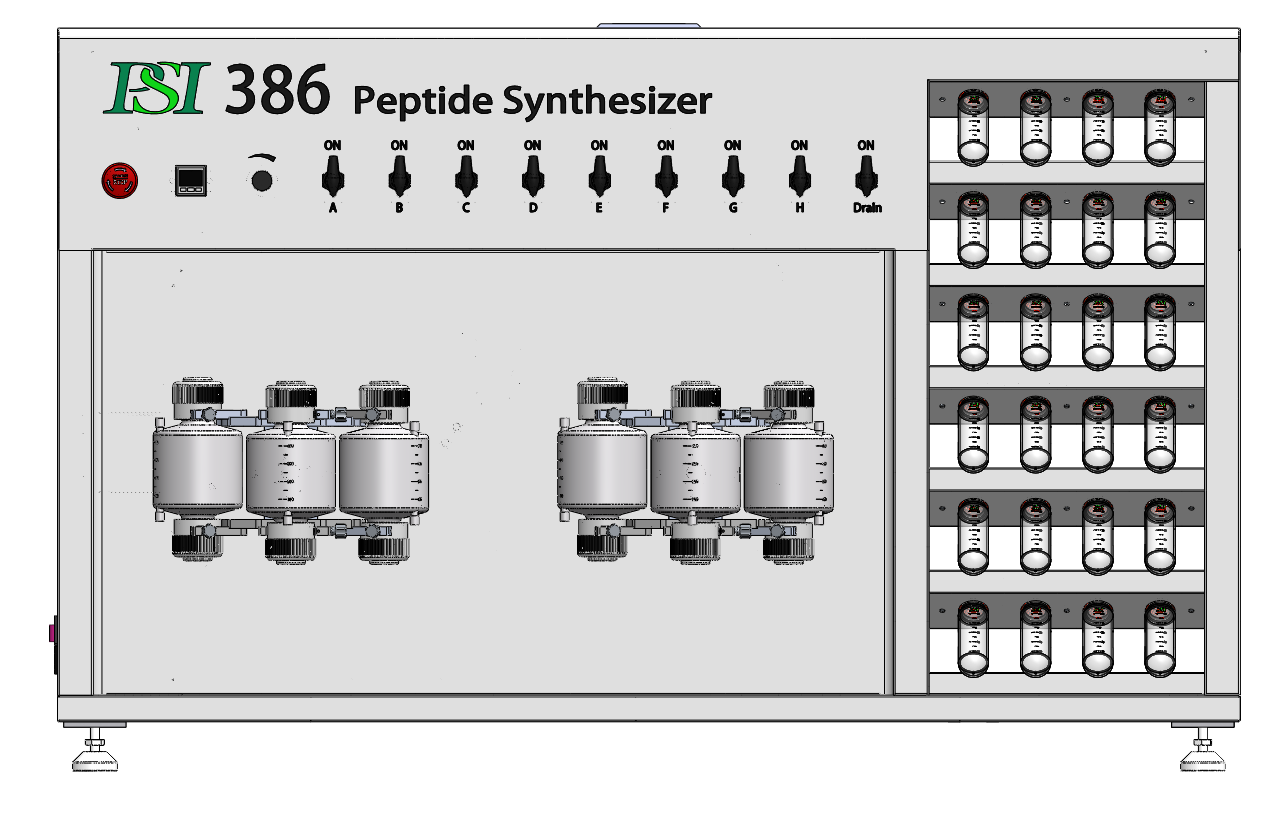

Operating Procedures and Tips for Solid Phase Peptide Synthesizer

Release Time:2024-05-21

Number of views:1880

Solid Phase Peptide Synthesizer is an automated equipment for chemical synthesis of peptides, which combines the advantages of solid phase synthesis method and automation to greatly improve the efficiency and purity of peptide synthesis.

I. Operation flow

1. Preparation stage: Firstly, we should prepare the amino acid, resin, solvent and other reagents required for the synthesis, and initialize and check the Solid Phase Peptide Synthesizer to ensure that the equipment operates normally.

2. Loading resin: Load the selected resin into the synthesis column and activate the resin by pumping and washing steps.

3. Coupling Reaction: According to the predetermined sequence, amino acids and coupling agent are added sequentially to carry out the coupling reaction of amino acids. In this process, the reaction time and temperature need to be strictly controlled to ensure the effective progress of the reaction.

4. Deprotection: after completing the coupling reaction, the protective groups on the resin need to be deprotected for the subsequent coupling reaction.

5. Repeat steps 3 and 4: Depending on the length of the peptide sequence, repeat the coupling reaction and deprotection steps until all amino acids are connected.

6. Cutting and desalting: The synthesized peptide is cut from the resin and desalted to obtain a pure peptide product.

7. Analysis and identification: The synthesized peptide is analyzed and identified by mass spectrometry and high performance liquid chromatography to confirm the structure and purity of the product.

Operation Skills

1. Optimize the synthetic sequence: When designing the peptide sequence, avoid using difficult amino acids or complex structures to reduce the difficulty of synthesis and improve the success rate.

2. Control the reaction conditions: Strict control of the reaction conditions, such as temperature, time, pH, etc., is essential to improve the efficiency of synthesis and product quality.

3. Selection of suitable solvents: Selecting suitable solvents can improve the reaction speed and solubility of the products, which is conducive to the smooth progress of the synthesis process.

4. Prevent cross-contamination: In the operation process, laboratory norms should be strictly observed to avoid cross-contamination between reagents.

5. Pay close attention to the state of the equipment: in the synthesis process, we should always pay attention to the operating status of the equipment, and find and solve problems in time.

6. Reasonable allocation of time: Reasonable arrangement of the synthesis tasks and time, to avoid neglecting the experimental details to ensure that each step is done properly.

By following the above operating procedures and techniques, the solid phase peptide synthesizer can be used effectively for peptide synthesis. During the whole process, the operator should have solid theoretical knowledge and practical experience in order to flexibly respond to various problems that may arise.