Guidelines for Safe Operation and Maintenance of High-throughput Peptide Synthesizer

Release Time:2024-03-26

Number of views:1037

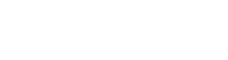

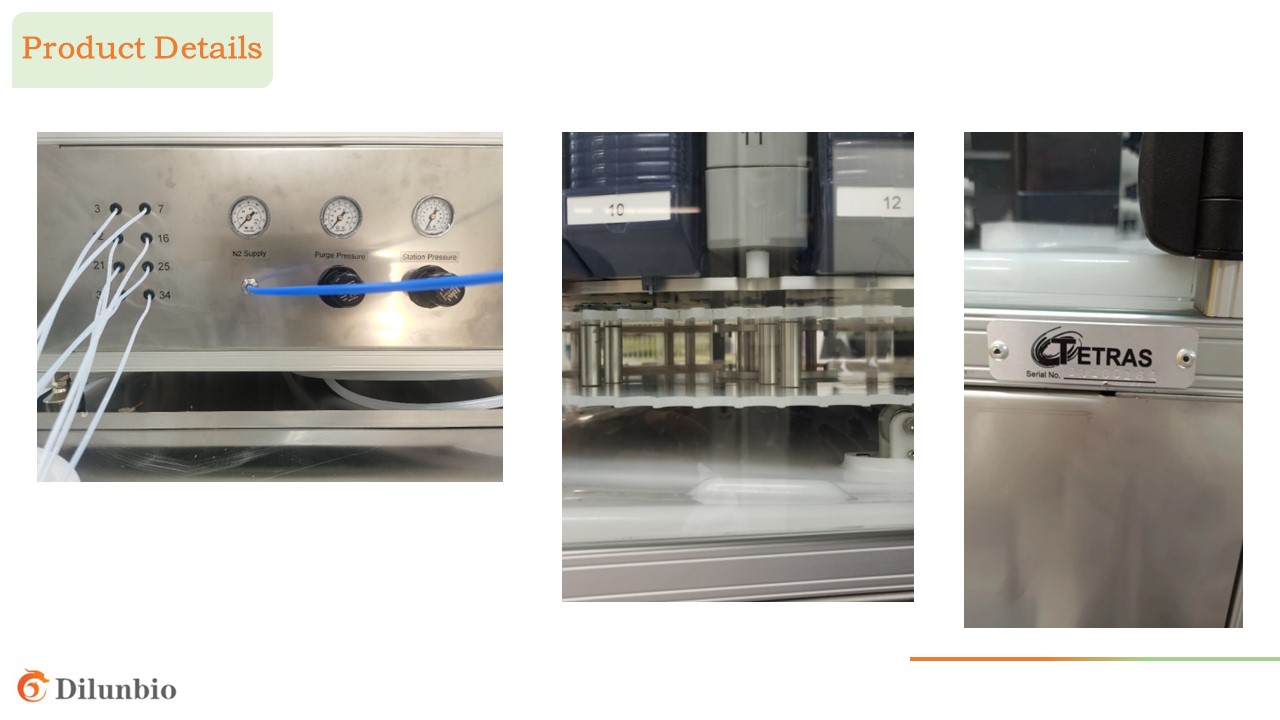

High-throughput peptide synthesizer is an advanced equipment for large-scale synthesis of peptide compounds, which is widely used in biotechnology, drug development and other fields. In the process of using it, safe operation and equipment maintenance are especially important.

I. Safe Operation Guidelines

1. Preparation before use

Before use, the operator should receive professional training and be familiar with the operation methods and safety regulations of the equipment. At the same time, ensure that the equipment is installed in a suitable environment to avoid strong light, high temperature, humidity and other adverse conditions. Also check whether the accessories of the equipment are complete to ensure the normal operation of the equipment.

2. Operation steps

During operation, the operating procedures should be strictly followed. First, configure the appropriate reaction system according to the experimental requirements, including substrate, catalyst, solvent and so on. Then, add the reaction system into the reactor of the synthesizer and set the reaction conditions, such as temperature, time, pressure and so on. Finally, start the synthesizer and wait for the reaction to complete.

3. Safety Precautions

In the process of operating the high-throughput peptide synthesizer, the following safety precautions should be noted:

(1) Avoid contact with harmful substances. Harmful chemicals may be generated during peptide synthesis, and the operator should wear protective equipment, such as protective glasses, gloves, aprons and so on.

(2) Avoid high pressure and high temperature. High pressure and high temperature may be generated during operation, and operators should keep a safe distance from the equipment to avoid burns or injuries.

(3) Observe electrical safety regulations. It is electrical equipment, and the operator should comply with electrical safety regulations during use to avoid electric shock accidents.

II. Equipment Maintenance Guidelines

1. Cleaning and Sterilization

After use, the equipment should be cleaned in time to avoid damage to the equipment caused by residual substances. During the cleaning process, mild detergent and soft cloth should be used to avoid scratching the surface of the equipment. In addition, the reactor, piping and other parts of the equipment should be sterilized regularly to ensure the accuracy of the experimental results.

2.Replacement of accessories

Some of its accessories, such as reactors, pipes, pumps, etc., may be worn or damaged after long-term use and need to be replaced. Operators should check the fittings in time when the equipment is abnormal.

3. Regular inspection and maintenance

Regular inspection and maintenance should be carried out, including the electrical system, mechanical system, control system and other aspects. Operators should record the running condition of the equipment, and if there is any abnormality, they should notify the professional personnel for maintenance in time to avoid the equipment running with disease.

4. Environmental requirements

It should be installed in a clean, tidy and ventilated environment, avoiding direct sunlight, humidity, dust and other adverse conditions. In addition, there should be enough space around the equipment for easy operation and maintenance.

Safe operation and maintenance of the High-throughput Peptide Synthesizer is crucial for the accuracy of the experimental results and the service life of the equipment. Operators should strictly follow the operating procedures and perform regular equipment maintenance to ensure the normal operation of the equipment.